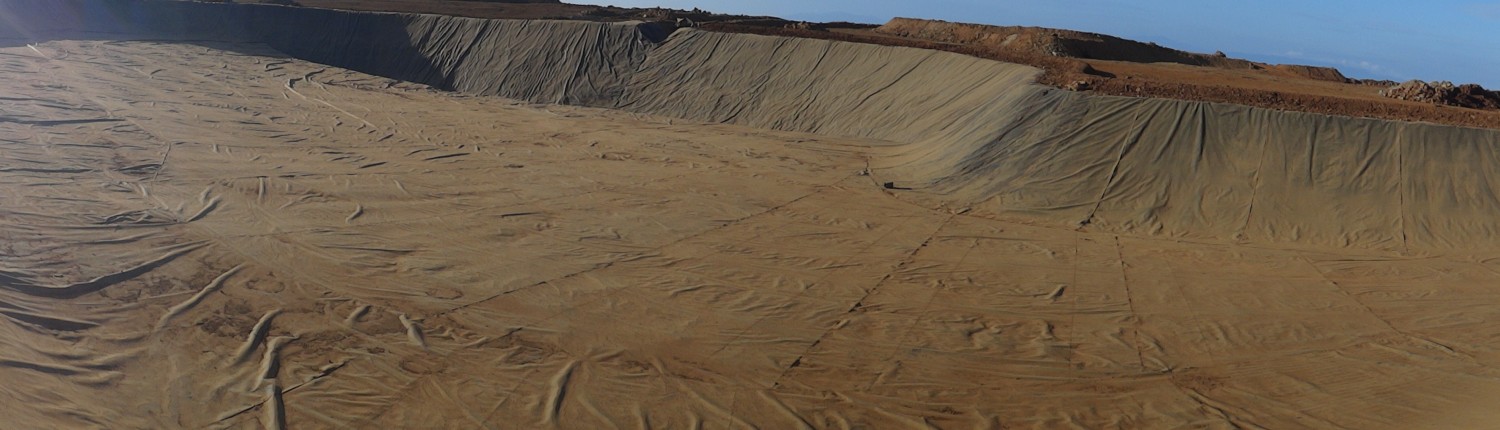

Geomembranes are made of premium Polyethylene (HDPE or LLDPE) resins which are specifically processed. These materials are excellent in retaining water and prevents seepage by creating an Impermeable Liner.

Geomembranes provides an effective and efficient solution for waterproofingSave layer on various applications. This product has a range of thickness of 0.5mm-3.00mm.

Fabrimetrics Phils., Inc. also provides experienced technicians and personnels for geomembrane installation. We are equipped with complete tools like:

Wedge Welder

Extruder

Hot Air Blower

Vacuum Tester

We are a PhilGEPS platinum member. We have the necessary expertise and 25 years of experience in dealing with municipalities, cities, and other government institutions. We also deal with the Philippine navy, coastguard, and the army. In emergencies, we have also supplied our products swiftly and efficiently in disaster areas.

Strengths

Impermeable

Watertight

Economic and Effective

Resistant to UV (Ultraviolet Light) Degradation

Resistant to Chemical Substances and Micro Organism

Strong and FlexibleStable

Long-term Performance

Easy and Quick Installation Process

Applications

Landfill Foundation and Landfill Caps

Toxic Waste Containment

Liquid Waste Containment

Aquaculture Ponds

Drainage Pipeline

Water Reservoir

Dam Mining/Tailing Works

Tunnel Lining

Lake and Reservoir lining

prevent contaimation of ground water

Municipal waste management

Hazardous waste management

wastewater containment lagoons

Our Geomembrane or HDPE liner is used for water proofing. It is made of High Density Polyethyle (HDPE). It is colored black to resist UV degradation. Mostly used in dumpsites, tailing ponds, fishponds, lagoons, mining, and drilling. You can choose from a variety of thickness and then we fabricate the liner based on your specifications.

The available thickness are: 0.2mm, 0.75mm, 1mm, 1.5mm, 2mm

HDPE Geomembranes

HDPE geomembranes are products that are preferred for projects requiring liners with low permeability ,ultraviolet resistance and exceptional chemical properties, which makes them cost-effective for applications, such as:

Hazardous Waste Landfills

Solid Waste Landfills

Containment for Animal Waste

Pond Liners

Tank Liners

HDPE is an excellent product for large applications that require UV and Ozone resistance, chemical resistance or high-quality installations. Typically used in landfill and mining applications, this product is delivered in large rolls with a width of 4 to 7.5 meters and is heat welded in the field by trained technicians providing a high quality, test certified installation. HDPE offers the most cost effective liner for large projects. HDPE is available in thicknesses ranging from 0.2mm to 3mm

HDPE Liners are a cost effective choice for lining projects that are exposed to sun and rain. It is used in landfills, lagoons, animal waste ponds and mining, and power plant applications.

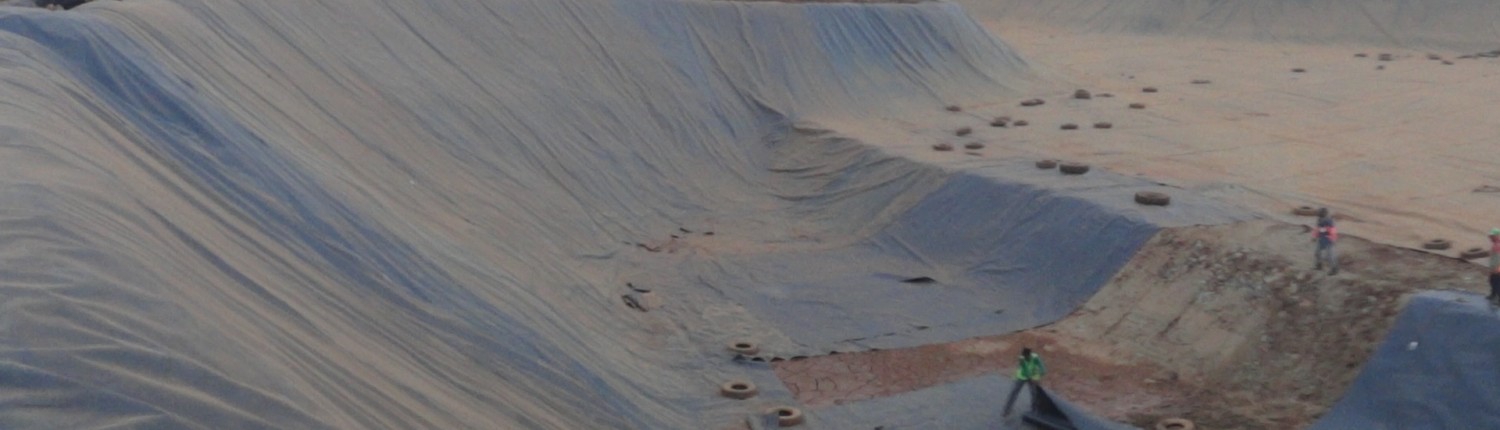

Installing

HDPE requires specialized welding equipment and certified welding technicians to be installed properly. The most common method of securing the liners on side slopes is by means of an anchor trench around the perimeter. A batten strip or an embed channel system is used to attach the liner to structures.

Seaming on site

Welding is done with hot wedges on long field seams, and extrusion welders are used on detail work and pipe boots. HDPE is delivered to the project directly from the factory in 4 to 7.m wide rolls and is fitted in the field to the design specification.

By fusion welding, heat is applied directly to both geomembrane panels by a hot wedge welder with speed control thren a series of rollers fuse both materials together. Extrusion welding is usually done to repairs on the liner material and on T-junctions formed by fusion.